Custom Sign Manufacturing

Avalis is first and foremost a custom sign manufacturer. Since 1989 we’ve accumulated a great deal of experience supporting architects, design firms, end-user customers, and commercial construction companies nation-wide.

At Avalis we believe that if you can give us a design, we can find a way to make that design a reality. Our experienced staff are masterminds at engineering solutions to make signs attractive and functional for our customers while paying special attention to the quality of the signs we produce. Our production department pays attention to the slightest detail to make sure the sign we hang on your wall is of the highest quality.

Avalis’ production facility is in Fort Collins, CO and consists of 5 different specialty departments that each focus on different aspects of the sign manufacturing process.

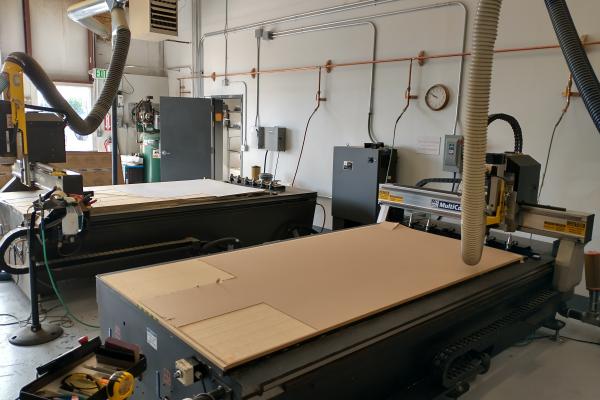

Once the project gets released to our production department, it typically starts with our CAM department. The CNC operators in the CAM department will cut all the material for the project on one of our two Multi-Cam CNC routers. These parts are binned up and moved to the next department which is typically our TAG department.

The TAG (Tactile and Graphics) department applies raised text and braille to the sign blanks and will also do final assembly. TAG also runs our digital printers to apply raised or flat digital print to a sign blank. The TAG department features two lasers, 2 braillers, and 2 digital printers.

Our Vinyl department will also do final assembly as well as applying vinyl copy and graphics to the signs. Our vinyl department has a vinyl plotter and a ton of vinyl color options. Connected to the vinyl department is our install department which is responsible for installing the signs we produce . We install a large variety of sign products and can install all over the country.

Our paint department is responsible for applying paint to sheets or to finished product. Our paint department can mix custom colors and can spray interior and exterior applications.

Our production associates are all cross-trained in different department so they can be moved around as needed but more importantly so they know what to look for when quality checking the previous departments work.